Our site uses cookies to ensure the quality of our services. By continuing to browse, you agree to our cookie policy.

Lightning-fast, economical metal tube cutting

With new advances in technology, you benefit from our increased speed and higher quality. We can quickly and easily custom cut your metal to your exact specifications, allowing you to jump into your project that much faster.

What gives LT Technologies our cutting edge?

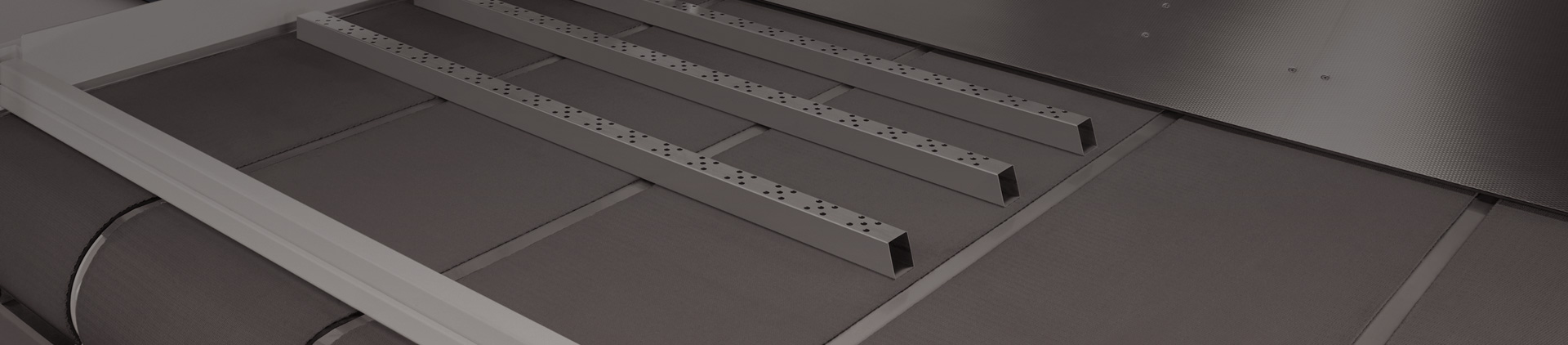

Introducing TruLaser Tube 5000 CO2 and TruLaser Tube 5000 fiber

We can cut or segment tubes of various diameters, and are able to process oval or rectangular tubes made from steel, stainless steel, aluminum, or other metal. We can perforate holes to your desired size and shape. With advances in clamping capability, we can manufacture tubes across the entire clamping range without the need for retooling.

The state-of-the-art sensor system in theTruLaser Tube 5000 fiber ensures that the entire machine process runs smoothly. Precision collet chucks hold tubes in place without damaging your materials, and the self-centering clamping system with continuous sensor monitoring adapts to every tube’s geometry.

Utilizing the RapidCut system, high feed rates of the solid-state laser allow for maximum precision even on smaller contours and a wide range of special profiles. We can handle tubes—even long ones—of different diameters and wall thicknesses while still maintaining top productivity.

We have the capacity, experience, and knowledge to handle your largest production demands. Countless industries, ranging from agricultural to automotive to medical, depend on our services. Talk to us today about how we can help empower your business.

.jpg)